ALWAYS IMPROVING

01/29/16 — Farm

Photo by Scott David Gordon

Photo by Scott David Gordon

From the Farmer's Perspective

One of the things that motivates me to farm is the need for continuous improvement. When I do the same things all the time, I lose interest, so luckily I've found myself in a job where nothing stays the same for long. I'm the kind of guy who is full of ideas - my staff can tell you, sometimes I drive them crazy with the timing and frequency of them. But 2015 was a hard year for the farm. With two major flood events, my focus has been determinately set on problem solving in the present - salvage, recover, replant - instead of the future. This week was a step back into my old self though - I busted into Krishna's office twice with aha! moments and now I feel ready to dive into 2016 full on.This week I'm talking about some of the things we design behind the scenes to make sure your veggies show up each week.We're making some serious improvements right now at the farm - take our harvest management system, for example. Every day at JBG, there are harvest needs in four very different departments - CSA, farmers markets, restaurant sales, and wholesale accounts - that need to be picked, sorted, packed, and delivered, usually within 24 hours. Two years ago, every department manager would individually call or text Vicente, our harvest manager, with their orders! Vicente would sit in his "office" (pickup truck) on the phone the whole day, keeping track of these numbers in his notebook. Talk about inefficient.

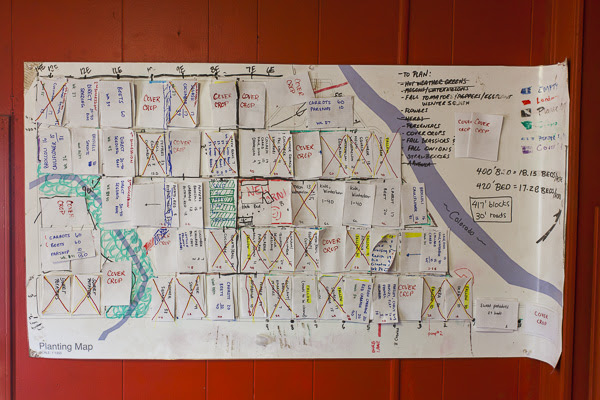

We have to do a lot of planning at JBG, from field plans to harvest management, and more, to ensure our complex system runs smoothly.

We have to do a lot of planning at JBG, from field plans to harvest management, and more, to ensure our complex system runs smoothly.

Then, we moved to an electronic system designed by employee Mike Reed. Mike, who is a spreadsheet wizard, took ALL of the information needed from each department and turned it into one monster of an Excel spreadsheet that consolidated and recorded numbers for harvest. As you can imagine, this spreadsheet was as complicated as the system it was designed for. It was a huge improvement - for Vicente, our managers, and for on-farm record keeping. But the spreadsheet had it's drawbacks as well - managers were exceptionally good at breaking it, putting numbers in the wrong places, or replacing code with fixed values. Mike was the only one who knew the spreadsheet in and out, and so was the only one with the knowledge to fix it! I knew something had to change.

One principle that has guided me in my years of farming is the K.I.S.S. Principle - Keep It Simple, Stupid. We couldn't keep relying on a spreadsheet that was too complicated for our managers to effectively use. So, with the help of Krishna and his amazing wife (who happens to be a great coder), we've implemented a new harvest management system this year. It's simple, easy to use, has a friendly interface, and most importantly - has precautions against people trying to break it! We used all of the lessons learned in our first harvest management spreadsheet, keeping only what we needed to effectively communicate with everyone on the team. Keep it simple, stupid. The JBG staff has been really happy with the changes, and I've seen awesome improvements! For example, with the new system, our farmers market managers have input to tailor each farm stand to the customers that shop at that particular location - cool, right?

Our market managers will now have be able to customize their markets to fit their customers! Photo by Scott David Gordon

Our market managers will now have be able to customize their markets to fit their customers! Photo by Scott David Gordon

The next big improvement I'm looking forward to is creating a detailed look into every crop - labor costs, yields, sales, everything we need to know exactly which crops are profitable and which we still need to work on to get them there. One of my most read authors is Richard Wiswall - he's an expert on farm profitability and appropriate business tools and someone I look up to very much. I think it's important as a farmer to make sure that my teams aren't killing themselves to grow things that just don't work for us, and I'm excited to learn about all of our crops in depth.

Chef's Garden in Huron, OH (Ryan Kellman/NPR)

Chef's Garden in Huron, OH (Ryan Kellman/NPR)

This may not sound interesting to someone who isn't a full-time farmer, so let me try to put it into perspective. I really enjoyed reading this NPR article this week about the Chef's Garden in Huron, Ohio. These guys are some of my farmer heroes, and what they are doing for the land and their customers is just awesome. You might read this article, look through the pictures, and see a beautiful farm growing specialty crops. I see a whole lot more - I see three generations of farmers who have been working for at least as long on improving their farm processes. They are doing everything they can to produce the best soil, and the best veggies on that soil. And they know exactly what the costs are to grow food in this very special manner - the article notes that prices from the Chef's Garden are about 2.5 times more than a regular production system. They aren't short-changing their efforts and they sell to customers who know what they are getting for their money.

Ryan Kellman/NPR

Ryan Kellman/NPR

When you see the photo of their farm's packing facility, you probably just see a big warehouse of veggies. I see a great deal of inspiration for the future of JBG in the details. I see a refrigerated room for sorting and packing, keeping the cold chain intact and the produce at its freshest. I see that there is good flow, easy movement, and great placement of tables and machines for the tasks at hand. I see drains on the floors and stainless steel surfaces and ten other things that guarantee the highest level of food safety in their facility. These are all plans for our future JBG facility and it's encouraging to see these farmers doing it. It's a result of that same dedication to constant improvement. We would be bored without the challenge!

0 ITEMS IN CART

0 ITEMS IN CART